The group's research objectives are to increase energy utilization efficiency and to empower individual’s creativity through innovative manufacturing processes and systems, and through a better understanding of material behavior and process mechanics. The objectives ultimately lead to a comprehensive research portfolio in the research group, which includes mechanics of materials subjected to mechanical deformation, electrical and/or magnetic fields, predictive process modeling, sensors and process control, cloud manufacturing, and new process development in dieless forming, composite sheet forming, microforming and laser micromachining.

Current Research Projects

Past Research Projects

Advanced Manufacturing Processes Laboratory

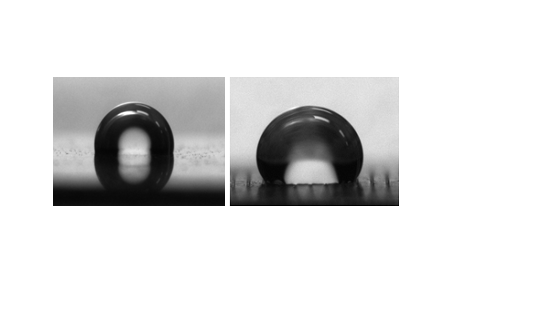

Surface Texturing

Square texture improves the hydrophobicity of AA3003H14 surface. (Left) Surface without texture; (Right) Surface with texture

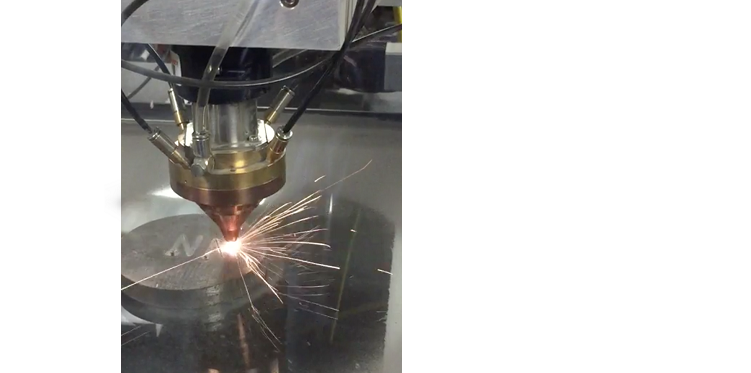

Additive Manufacturing

AMPL is working on rapid certification and new process development in DED processing for tool path generation and parameter control for desired microstructure and component geometry. Modeling efforts and in-situ monitoring for temperature and defects allow for controlled processing.

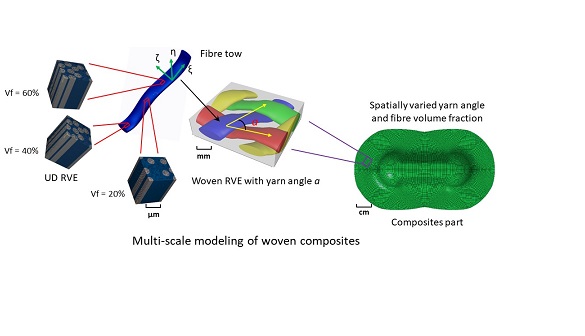

Integrated Forming Optimization Performance Analysis

The main objective of the Integrated Computational Materials Engineering (ICME) project is to develop, integrate and implement simulation tools for Carbon-Fiber Reinforced Polymer (CFRP) composites.

Rapid Dieless Forming Technology

The AMPL team created a state-of-the-art video, presenting the Double-Sided Incremental Forming process. DSIF uses stylus-type tools to form a part from opposite sides. (video after the link)

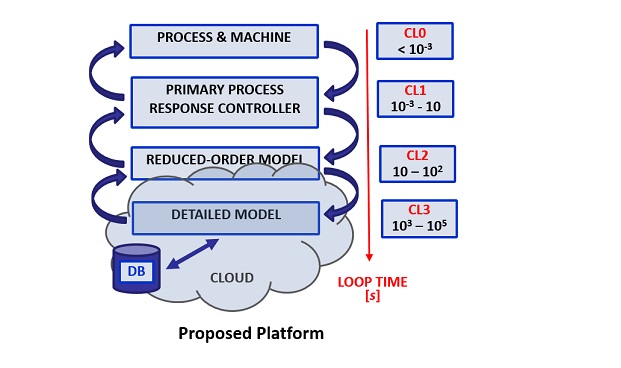

Cyber Physical System Data Structure

An Integrated Simulation and Process Control Platform for Distributed Manufacturing Process Chains