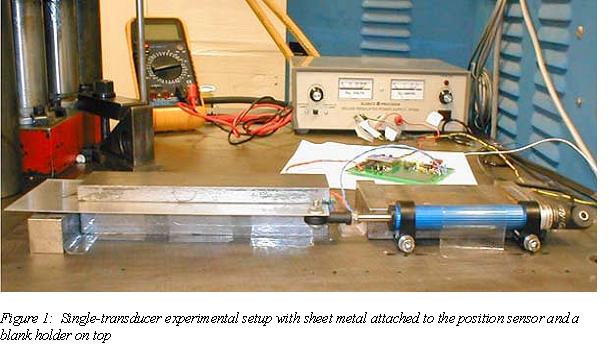

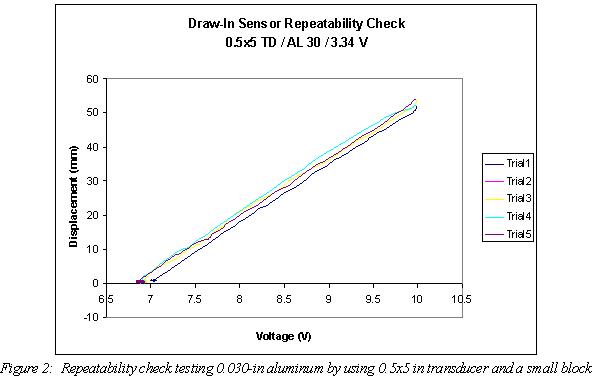

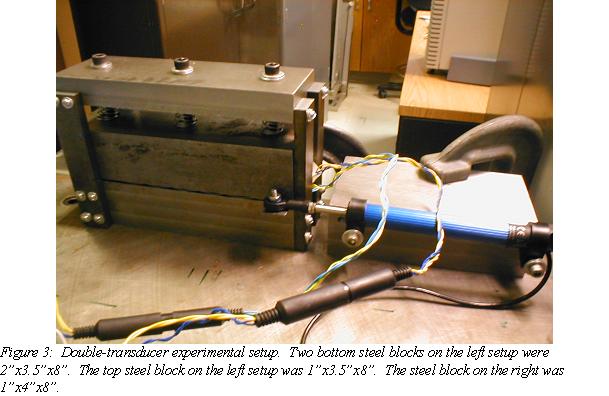

Sheet metal forming is one of the major processes in manufacturing and is broadly used due to its high degree of design flexibility and low cost. In the sheet metal forming process, draw-in (deformation of punched sheet metal) frequently occurs and lessens the effectiveness of the process. Currently, monitoring and controlling draw-in during each stamping operation is unfeasible, time-consuming, and used only in laboratory settings. However, one of our previous prototypes was developed to monitor draw-in and produced elaborate results. Our goal was to design a draw-in sensor providing high sensitivity in monitoring; ease of setup, measurement and controlling; and eventually be implemented in industry. Based on our previous prototype, we considered physical factors affecting the relationship of the results and examining which dimension of the transducer provides the highest sensitivity. The results showed good linearity and insensitivity to pulling speed and starting position of a sheet metal. One major finding of the results was the effect of material type to sensitivity since the draw-in sensor offered high sensitivity to aluminum but low sensitivity to steel. In addition, the induction of the transducer could be affected by the movement of the blank holder. The invention, implementation, and integration of the draw-in sensor will have an enormous impact on revolutionizing the stamping process and provide solid ground for process variation and uncertainty studies.