Motivation

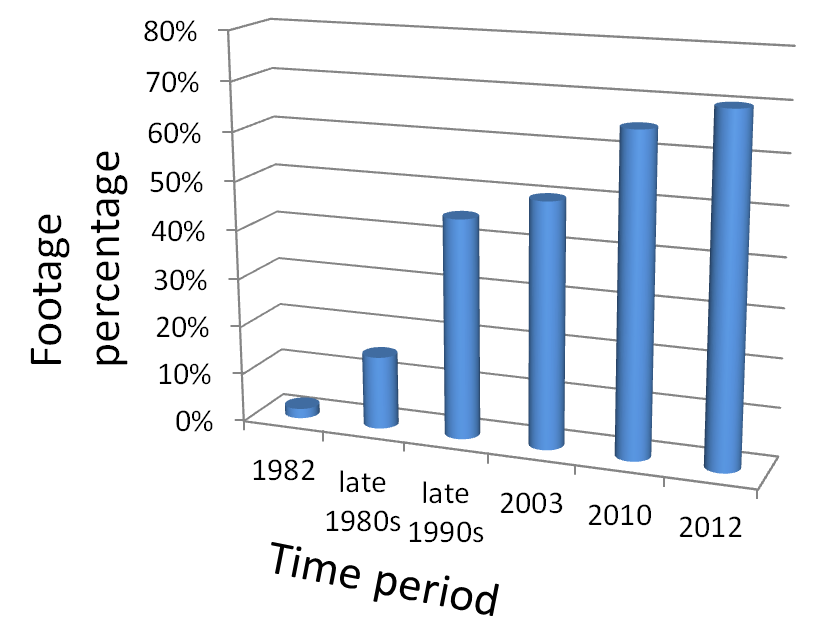

The strong strategic impetus for energy independence and reduced energy costs imposes the need for more efficient energy exploration and extraction. However, the various forms of hard rocks in the earth's strata pose a serious problem for efficient oil and gas well drilling, which currently costs over $30 billion/year in the US alone. Polycrystalline diamond compact (PDC) inserts, first introduced by General Electric in 1973 have been sharing more than 60% percent of the total footage of oil wells drilled worldwide due to their high rate of penetration, high energy efficiency, and long life, as shown in Fig. 1.

Fig. 1 - The share of PDC bits in the oil drilling market.

However, the performance of PDC bits is dramatically decreased in drilling hard rock formations, e.g., granite, chert, pyrite, quartzite, etc., which can be attributed to two barriers: (a) the still limited fundamental understanding of the rock cutting process with PDC bits in hostile environments, and (b) the lack of efficient and robust monitoring, diagnostics and control capabilities due to complex downhole conditions. Current research in our group is aimed to overcome the above-mentioned barriers by comprehensively studying the interaction between rock and cutter based on experimental, numerical and analytical methods.

Description

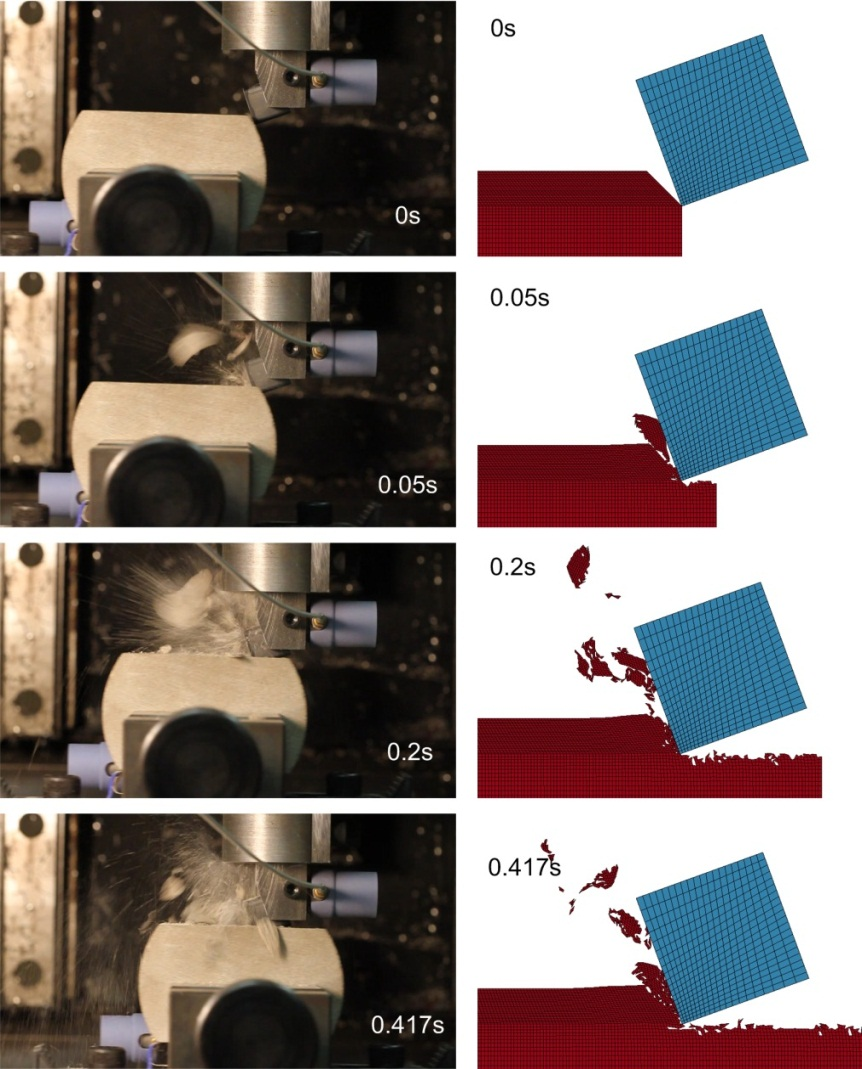

The ultimate goal of the current research is to gain fundamental understanding of rock cutting physics and capabilities as compared to current practice. The interaction between rock and PDC cutter during the rock cutting process will be implemented and characterized by experimental testing and then simulated and evaluated by finite element method. An advanced sensing technology will be developed and embedded onto the PDC cutter aiming to capture the force and temperature responses at the cutting edge during rock cutting. The most consequential impact will be the creation of fundamental scientifically and technologically enhanced oil- and gas-exploration capabilities and the opening of avenues for the emergence of innovative sensing and process monitoring and control technologies.

Approach

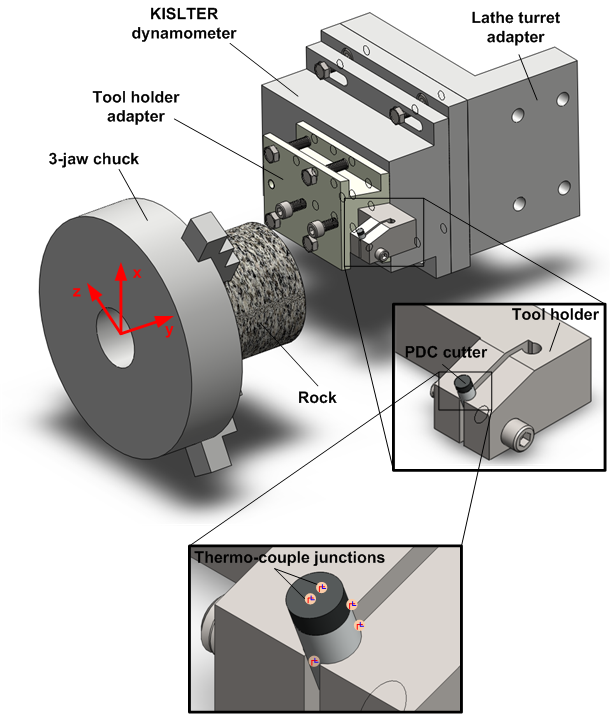

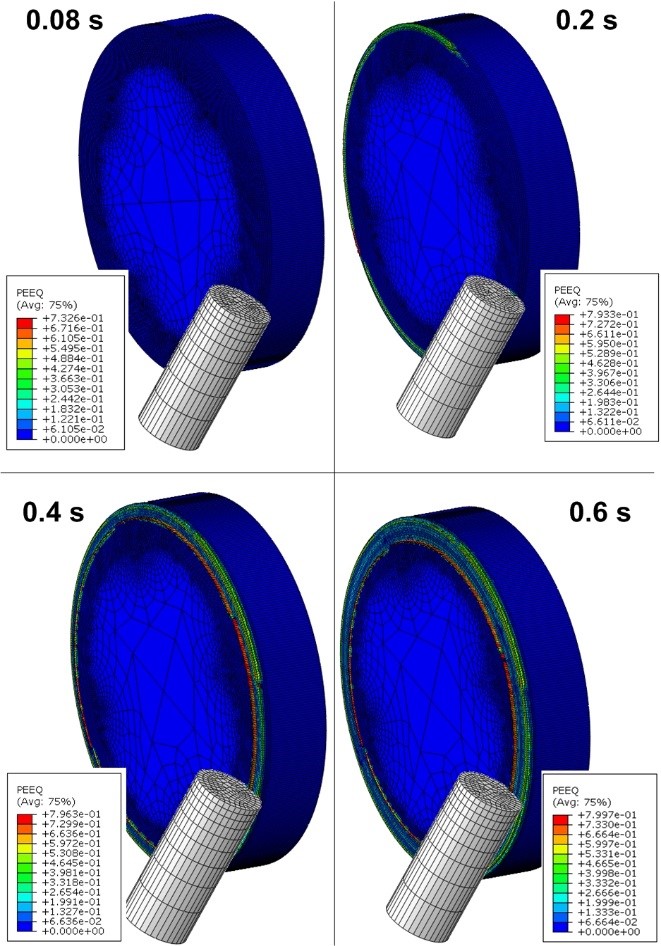

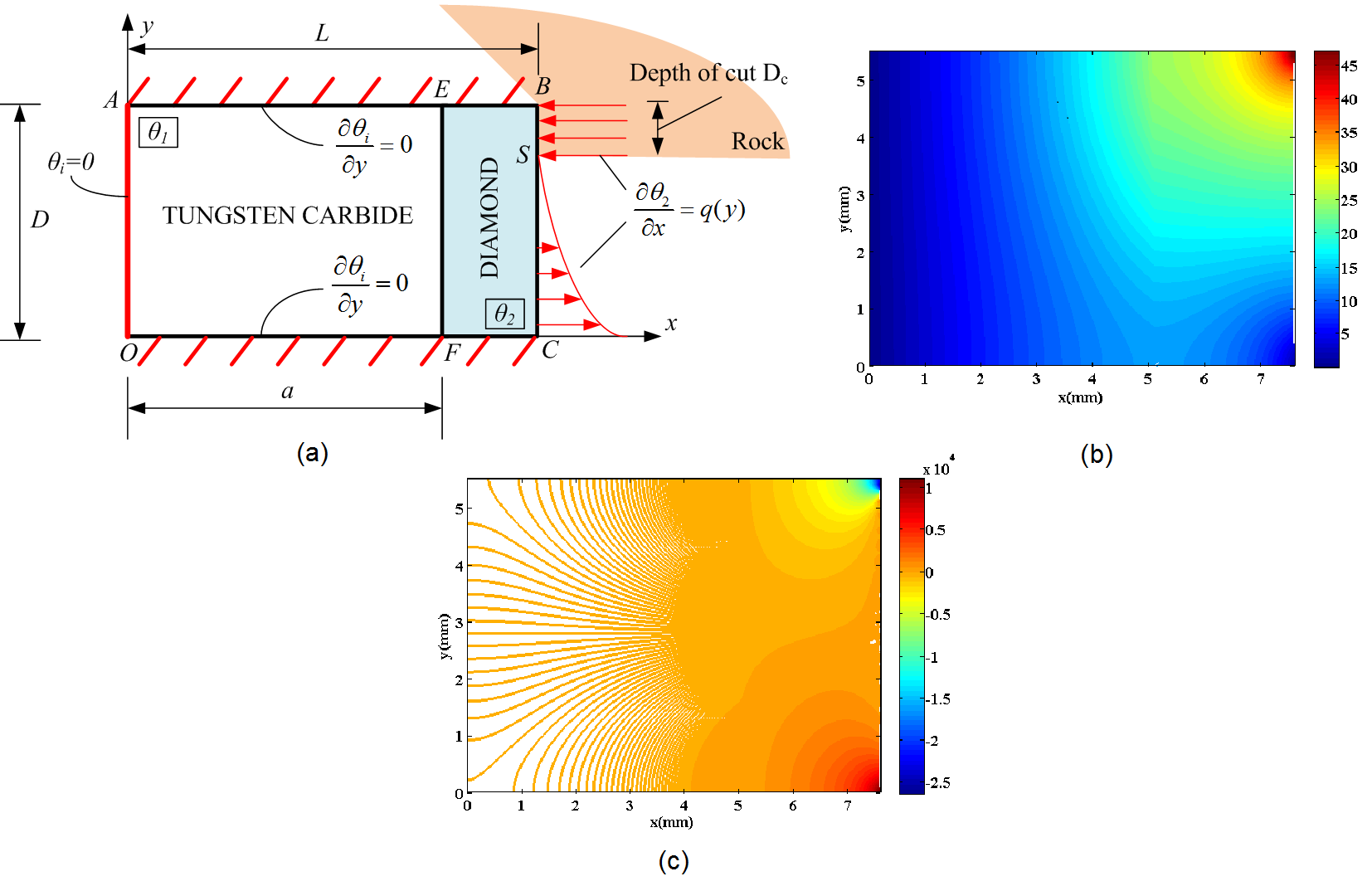

The rock-cutter interactions will be characterized under rotational cutting condition on a CNC turning machine and linear scrapping condition on a CNC milling center. The temperature, force and acceleration (dynamic) responses will be captured by a fully equipped sensing system. Analytical and numerical methods will be exploited to evaluate and predict thermal and mechanical responses as well as chip formations in the cutter during rock cutting. Moreover, an advanced sensing technology will be developed under the collaboration between Northwestern University and UCLA with the aim of capturing the thermal and mechanical responses of the PDC cutter at the region very close (~100µm) to the cutting edge. All above approaches will benefit the fundamental understanding of rock-cutter interaction and the optimization of cutter performance in field conditions.

Photos

Fig. 2 - Layout of rock face turning testbed

Fig. 3 - Chip formation comparison between experimental results and FEM predictions.

Fig. 4 - Analytical solution of heat transfer problem in 2D rock cutting: (a) problem formulation, (b) temperature response and (c) heat flux along x predicted by analytical solution.

Fig. 5. Finite element simulation of rock face turning process.

Sponsor

National Science Foundation (CMMI-1301127)