Motivation

|

Fig. 1 - Chandra X-ray Observatory: light path [1] |

The current X-ray telescope Chandra can provide high angular resolution to observe galaxies in space. The mirrors in the Chandra telescope were formed by polishing and grinding, and are thick, to obtain their desired shapes. This limits the mirrors’ collecting area sizes to about one square meter, due to weight constraints of the launch vehicles into space. In order to enhance the imaging capabilities of the next generation of X-ray telescopes, the aim is to increase the area of the mirror without making it too heavy. One option is to make thin mirrors. However, such a thin surface is flimsy and prone to deformation. Our ultimate goal is to be able to properly correct this deformation, so we can construct larger telescope lenses for use in the next generation of X-ray observatories.

Description

We can correct deformation by coating the non-reflective side of the mirrors with “smart” materials that respond to various stimuli, such as temperature changes, magnetic fields, or voltages.

This project specifically uses magnetic smart materials (MSMs) to try to counteract mirror deformation. We can use a magnetic field to actively control the surface profile of the mirror and consequently improve the quality of the telescope imaging.

Approach

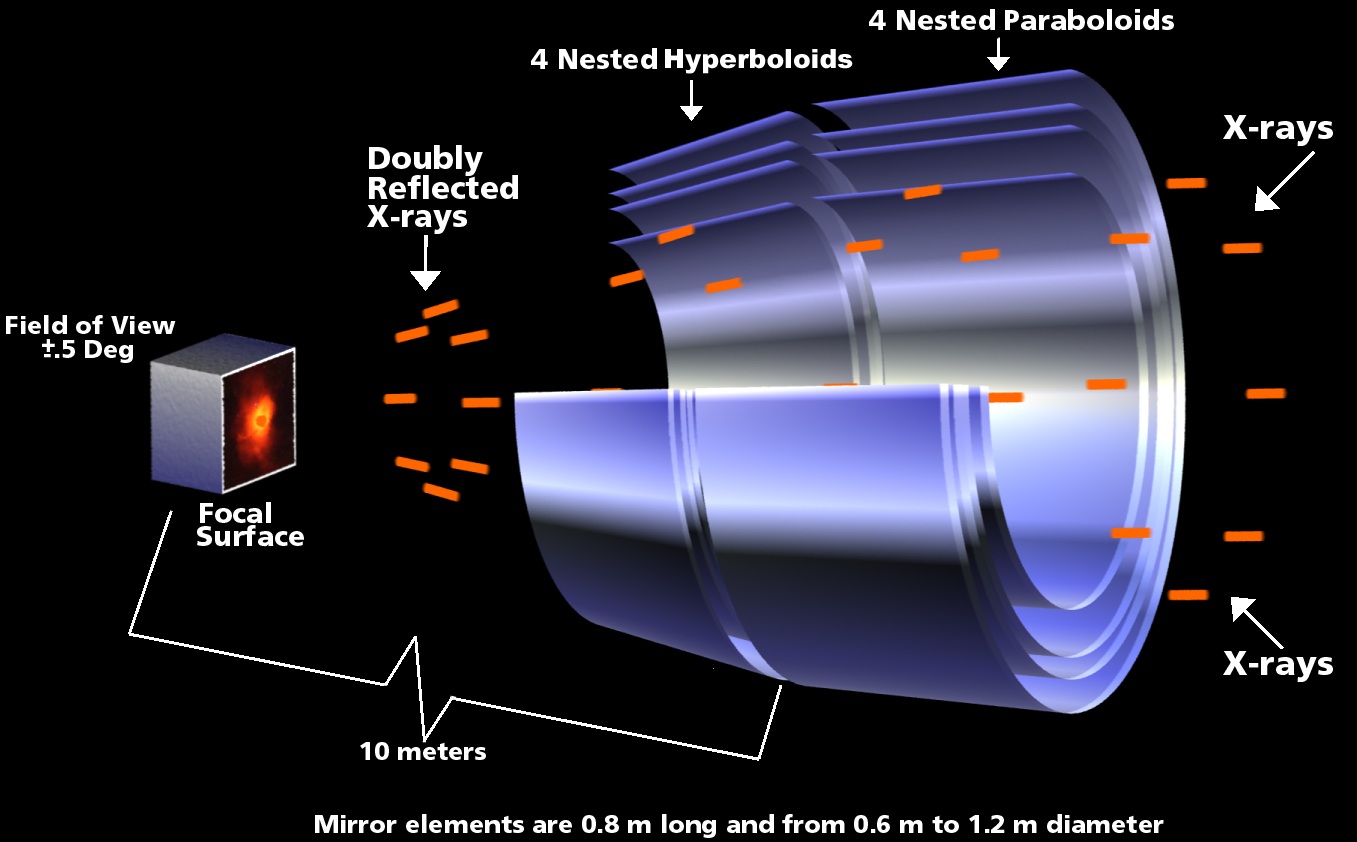

Fig. 2 - Chandra X-ray Observatory: schematic of

grazing incidence, X-ray mirror [1]

A specific animation for the grazing incidence X-ray telescope found here.

(http://chandra.harvard.edu/resources/illustrations/teleSchem.html)A magnetic write head will be applied to finely tune the surface profile of the mirror. However, it is not known exactly how magnetic write heads generate magnetic fields and how they would affect the radius of curvature and internal strain of the mirror. In this project, we are designing a magnetic write head. We aim to quantify the magnetic field around the write head and determine how it can be used to deform the sample coated with MSM.

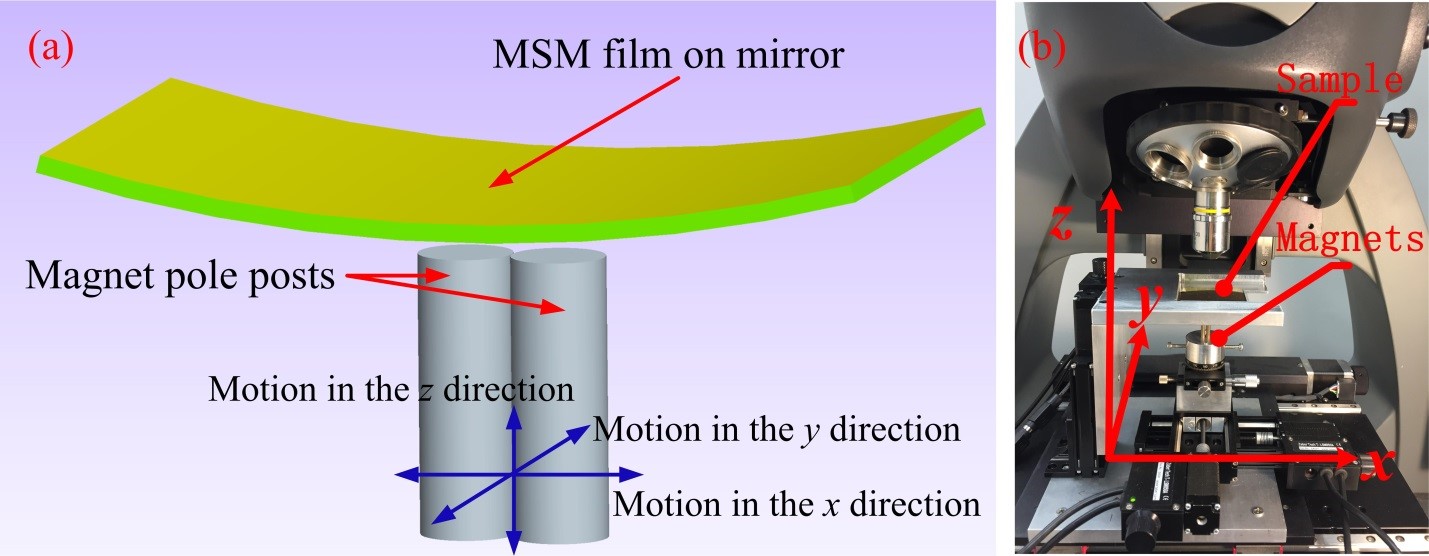

The bending of the specimen under the external magnetic field was measured using a Zygo White Light Interferometer (WLI) NewViewTM 7300, which has 0.1 nm resolution in the z direction (perpendicular to the x-y plane - the sample surface) and 2.21 μm resolution in the lateral direction. The schematic of the rectangular sample with local magnetic field applied is shown in Figure 3(a). The measurement setup is shown in Figure 3(b). The external magnetic field is produced via a pseudo-magnetic write head made up of two permanent magnet posts (3.175 mm diameter and 25.40 mm high). The magnet posts can be moved around the glass sample with a 3-d computer controlled translation stage. The system allows four degrees of freedom of motion, i.e., up and down, side to side, back and forth, and rotation of the posts about the vertical axis to allow us to change the orientation of the magnetic field in the (horizontal) plane of the sample. The surface profile of the specimen was measured using the stitch function by WLI.

Fig. 3 - (a) Schematic of a rectangular sample with local magnetic field applied; (b) experimental setup for measurements of surface profiles on 50 mm wide by 50 mm long pieces of 200 μm thick glass coated with ~ 4 μm thick Terfenol-D. [2]

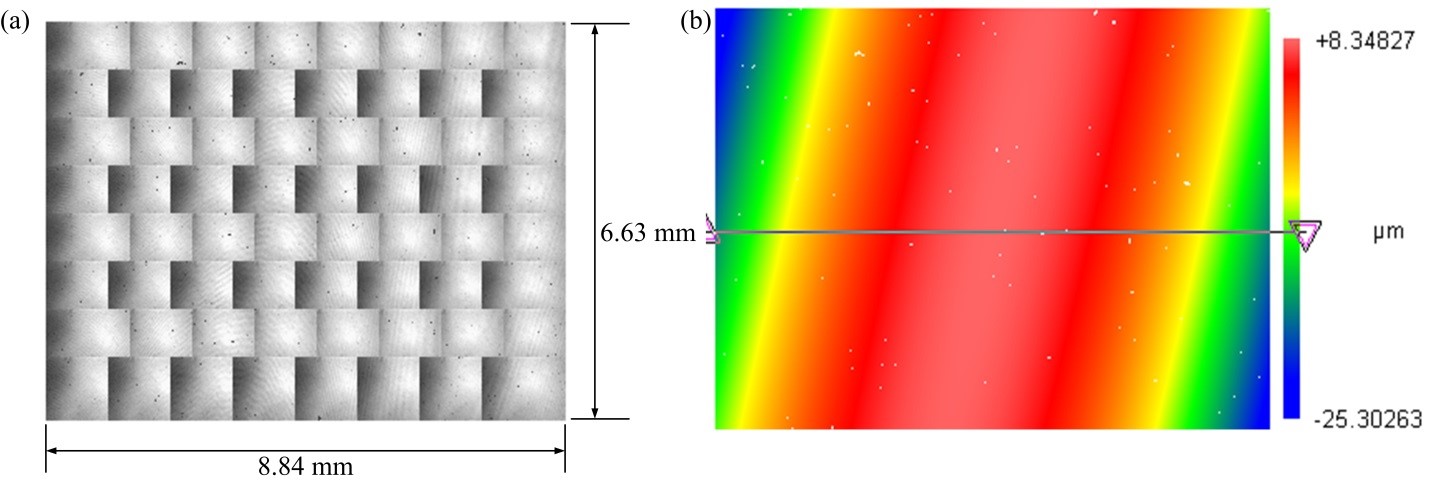

In the measurement, WLI scanned the local area on the sample surface from the same starting point every time for a certain sample. After the measurement, the surface profile of the sample was obtained as shown in Fig. 4.

Fig. 4 - Surface profile of the specimen measured by WLI, (a) surface map; (b) a contour plot of the surface profile, plus a horizontal line representing the position along which the average profile was determined. [2]

Sponsor

NASA (Grant NNX11AG05G)

References:

http://chandra.harvard.edu/resources/illustrations/teleSchem.html, 2011.

Wang, X., Yao, Y., Cao, J., Vaynman, S., Graham, M. E., Liu, T., Ulmer, M. P., Investigation of magnetically smart films applied to correct the surface profile of light weight X-ray optics in two directions, Proc. SPIE 9603, Optics for EUV, X-Ray, and Gamma-Ray Astronomy VII, 96031O, (September 4, 2015)