DSIF Micro-Double Sided Incremental Forming (µ-DSIF) at Micro-scale - (NSF AIR Project)

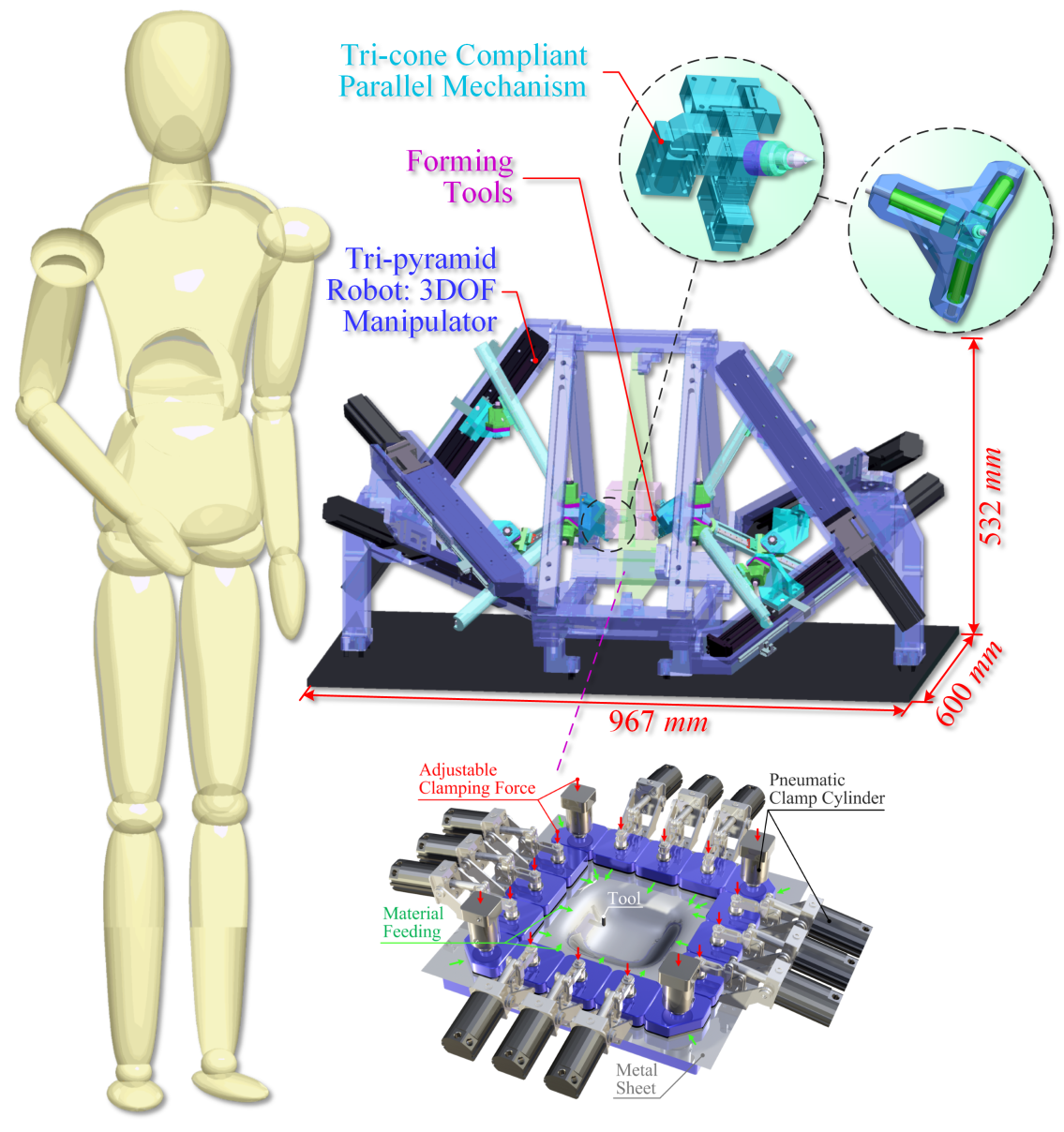

Micro-scale DSIF is to leverage our fundamental understanding of macro-scale DSIF and preliminary work in µ-incremental forming to design and fabricate a novel µDSIF desktop machine with a forming area of 80×80×80 mm. The new desktop machine with meso and micro-scale motions was designed by the PIs and named the Hybrid Tri-pyramid Robot. For the meso-scale forming process, the basic meso-motions of the forming tool can be easily realized by the newly designed Tri-pyramid Robot. The meso-motion accuracy of the forming tool will be maintained within a ±2.5 µm range. For the forming of micro-features however, an accuracy of ±0.1 µm will be required within an approximate 100×100×100 µm working volume, which can be implemented by a designed Tri-cone compliant parallel mechanism mounted on the output moving platform of the Tri-pyramid Robot.

New designed Hybrid Tri-pyramid Robot for micro-DSIF

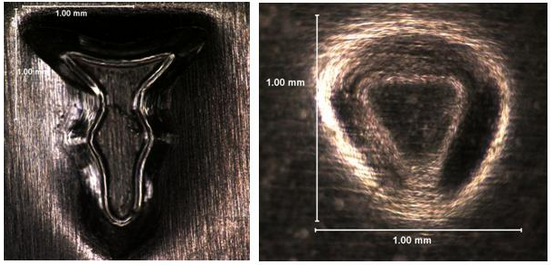

Preliminary work in µ-incremental forming process has been developed. These initial results show that incremental forming is in fact possible at the micro-scale. Also, the related fundamental micro-forming strategy pretreatment processes have been analyzed.

Freeform component and triangular pyramid formed by using incremental forming process

Sponsor

National Science Foundation (1414394)