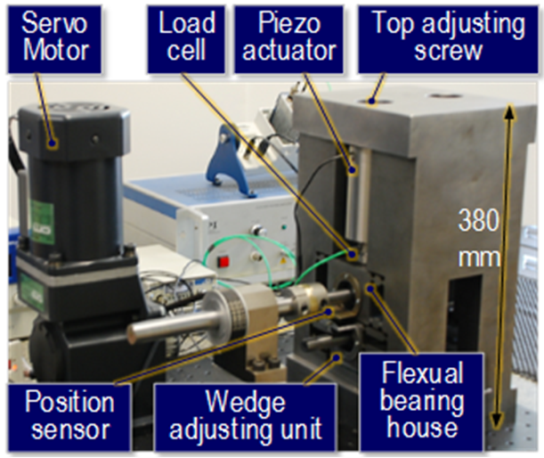

Desktop Microrolling Mill

A desktop microrolling mill (DµRM) was designed and prototyped for microrolling of sheet metals.

It is equipped with induction motors, piezo-actuators, capacitive position sensors and load cells.

The entire machine frame and the flexural hinges were cut from a single high-strength steel block by wire EDM, for compactness, structural stiffness and ease of precision control. The flexural hinges enable the movements of flexural bearing houses (FBHs) for roll gap adjustment.

The roll gap adjustment is done with a pair of piezo-actuators on the top of upper FBHs and a wedge unit under the lower FBHs. The piezo-actuator has the stiffness of 360 N/µm, resolution of 0.8 µm and resonant frequency of 4.5 kHz. It is capable of providing a maximum blocking force of 30 kN and pulling force of 3.5 kN. It has a maximum travelling distance of 80 µm.

The capacitive position sensors, which are attached on the sides of the lower FBHs, have a measurement range of ±2 mm with a resolution of 10 nm.

Load cells with 5 kN/μm rigidities and 30 kN load capacities are placed between the piezo-actuators and the upper FBHs for force measurements. The motion of the upper and lower rolls are controlled separately by two individual induction motors with speed control systems. The motor has a maximum torque of 530 lb-in and a maximum rolling speed of 15 rpm at 60 Hz AC power input. Rotary sensors with 0.1° resolution can be installed onto the shaft ends for angular displacement measurements as well.