RAPID Lumera Laser

Capable of micro-machining virtually any material

High precision control and flexibility

Diode pumped Nd:YVO4 picosecond laser

2W average power at 1064 nm

Second harmonics at 532 nm

High pulse energy - up to 30 µJ

High peak power of up to 20 MW

Beam quality: M²<1.2

Repetition rate: 10 KHz to 500 KHz

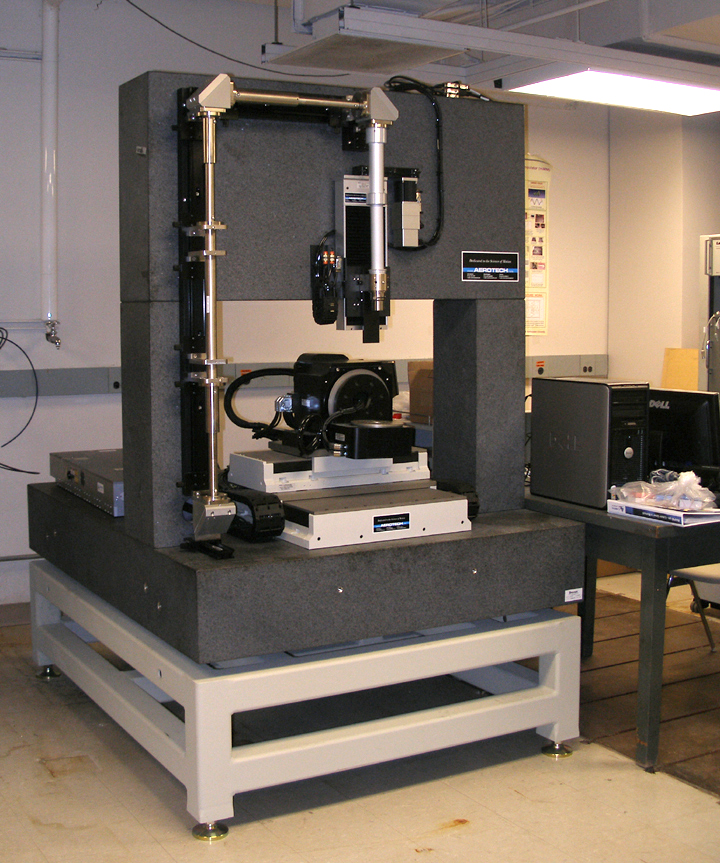

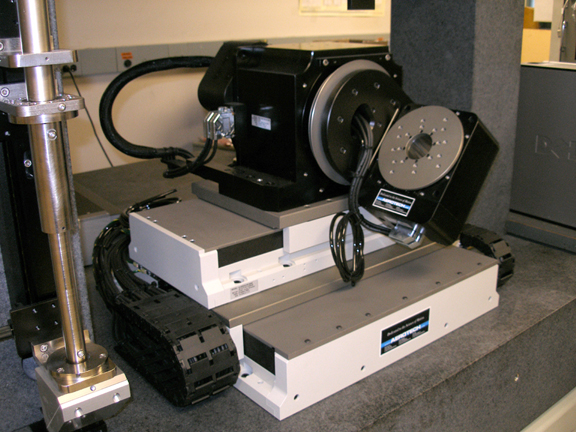

5 DOF Positioning System

Linear axes resolution of 10nm

Rotary axes resolution of 0.0001 degrees