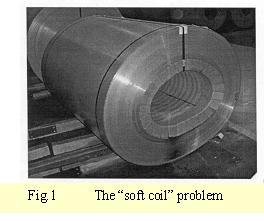

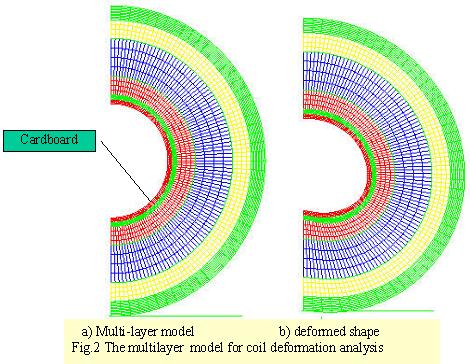

The soft coil problem observed in the production of laminate coils is shown in Fig.1. The factors influencing the formation of a soft coil include: sheet properties, winding tension, lubrication and cardboard stiffness. The objective of the present study is to quantify the contribution of each factor to deformation of a finished coil under gravity load. The approaches adopted in this study include: stress analysis of a finished coil, development of an equivalent material model to capture the deformation behavior of the coil and a multi-layer finite element model to compute the deformation of a finished coil under gravity load considering the non-uniformity of stress distributions in the coil, as shown in Fig.2.

Sponsored by:

Material Sciences Corporation.

Publications

Cao, J., Li, Shunping, Xia, Z.C. and Tang, S.C. (2000) "Optimization of Multi-Step Deep Drawing Processes Using Inverse and Incremental Finite Element Analysis", Journal of Materials Processing Technology Vol. 117, pp193-200. Abstract Full Paper

ao, J., Li, Shunping (2001) "Enhancement of a Coil Using a Cardboard Core" ASME International Mechanical engineering Conference & Exposition, West Lafayette, Indiana.

Cao, J., Li, Shunping (2002) "A study on the stress distribution in coil wrapping and its effect on final coil deformation" Proceedings of NAMRC XXX, soft coil phenomenon- Part I: Stress analysis and Part II: Coil deformation" submitted to International Journal of Mechanical Sciences.