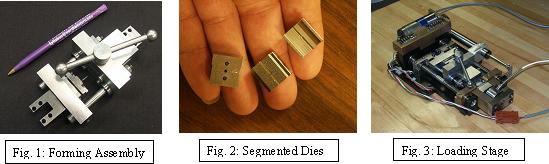

In the last ten years, miniaturization technologies have revolutionized product design and have lead to many innovative applications in the automotive industry, healthcare, environmental monitoring, defense, etc. The manufacturing processes used for achieving such miniaturization are numerous and vary from conventional techniques like machining to more complex MEMS-based approaches. This research focuses on one such technique, known as microforming. It is defined as the production of parts or structures with at least two dimensions in the sub- millimeter range. The effects of reducing the dimensions in a manufacturing process (commonly known as 'the size effect') have recently been studied by several researchers. Investigations using various experimental approaches have demonstrated the existence of differences in characteristics of both materials and processes between micro-scale and the conventional dimension range. These differences arise due to the effect of various factors such as grain size, surface roughness etc. that do not change when a process is scaled down geometrically. One example of a typical micro part is the connector pin, which is widely used in computers, communication devices and other electronic products. Together with other micro products, they have a market value of $45 billion in 2003 and enjoy an annual growth rate of 20%. Current manufacturing processes employed for the manufacture of connector pins are machining, folding, stamping, etc. These processes have some inherent disadvantages that make them unsuitable for mass production. For example, machining is a subtractive process that produces high material waste and has a high cycle time. Folding and stamping use sheet materials as input raw material and therefore, they restrict the geometry of the final part. This research endeavor explores the feasibility of using extrusion as a viable process to manufacture micro parts like the connector pin. The extrusion process is not only a fast process that can achieve high precision, but also a process with high material utilization (100% in theory). In this research, we developed a novel experimental setup consisting of a forming assembly (fig. 1) and segmented dies (fig. 2) used for extrusion of micro-pins. The forming assembly is designed to be mounted in a loading stage (fig. 3) that measures the ram force and ram displacement during extrusion. Using raw materials of different grain size and dies with different surface roughness values, the effects of these parameters are being investigated.

The design and functioning of a novel, hi-speed, desktop microextrusion machine is developed (see figure below). The machine enables the user to run extrusion experiments at speeds varying from 25mm up to 200mm, thus serving as an experimental tool to investigate the microextrusion process at strain rates that are comparable to conventional, commercially available microextruders. The compact modular design also lends itself to modifications that enable the user to change the dimensions of the extruded part by making small changes to the die, the ram and the ejector pin. The overall shoe-box size of the machine, conventional 3-phase power supply, generic control system and overall weight make the microextrusion machine suitable for inclusion into a microfactory.