This project is a partnership between Purdue University and Northwestern University and a number of private sector institutions created to enhance laser manufacturing and materials processing technologies.

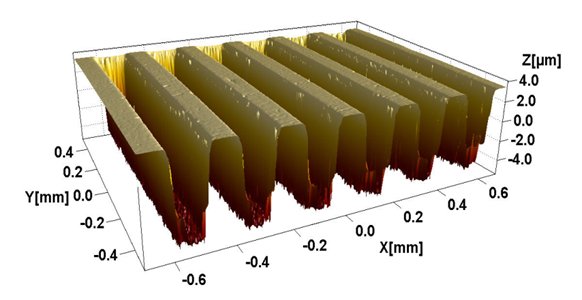

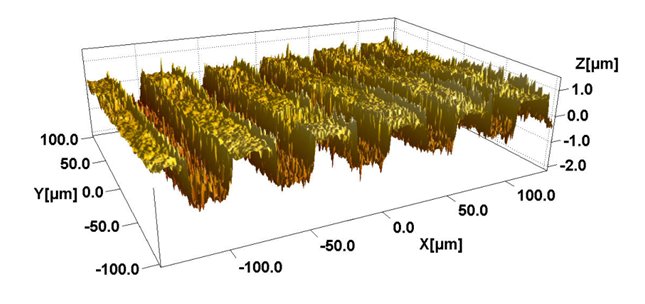

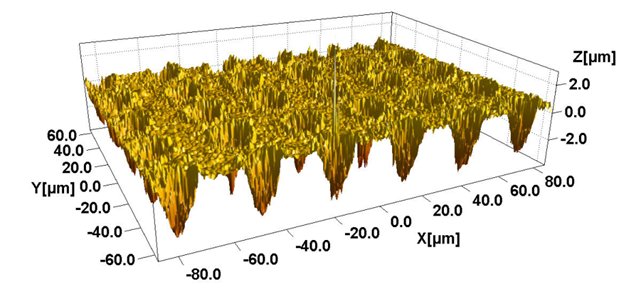

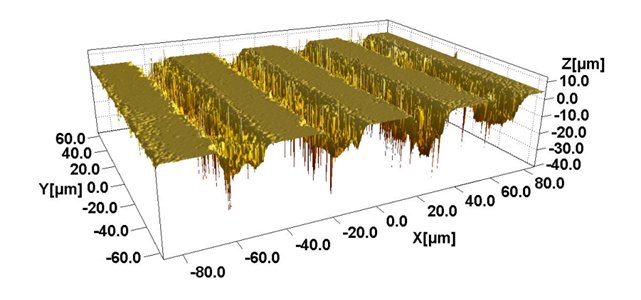

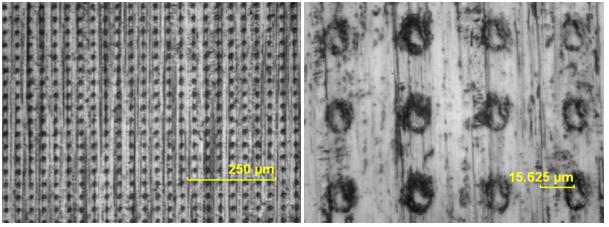

Laser micro-machining is one method of surface texturing that utilizes high-intensity pico or femto-second laser pulses to incrementally ablate, or vaporize, minute segments of the substrate material to create the desired feature geometry. Current work and results to date are summarized below. A detailed description of Northwestern’s state-of-the-art laser micro-machining and surface engineering system can be found here (link). Examples of some textures we have created are shown below:

Channels textured on stainless steel with a depth of 8µm and width of 110µm. The sample was polished after texturing.

Channels textured on copper with a depth of 2µm and width of 25µm.

Dimples textured on aluminum with a depth of 3µm and spacing of 30µm.

Channels textured on quartz with a depth of 10µm and width of 20µm.

Friction Reduction

Friction reduction via surface texturing can be beneficial in a wide variety of disciplines. For example, in the automotive industry, a significant improvement in fuel economy could be realized through texturing of various engine components. In biomedical applications, texturing of replacement joints has the potential to vastly improve the wear properties, thereby increasing product life. Reduction of friction and wear ensuing from this growing technology could result in improved energy efficiency and an extended product lifecycle, ultimately conserving both fuel and raw materials.

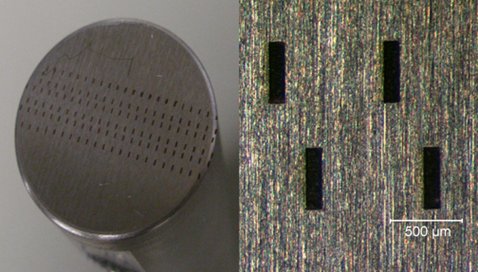

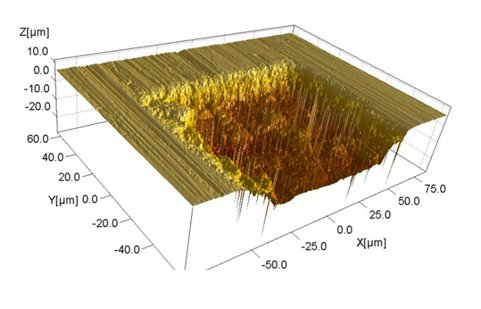

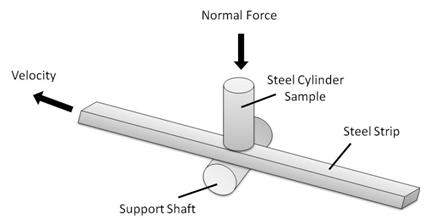

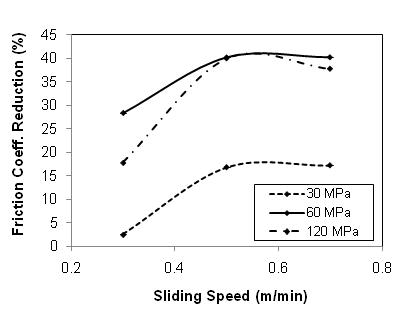

To determine the effect of texturing a sample in a flat-on-flat contact situation, we textured the flat end of a steel sample in the configuration shown below (microscope and cross-sectional views of a single dimple). A steel strip was pulled across the surface at a known speed and normal pressure and friction forces were recorded. The results showed that friction was reduced in all cases in comparison with a non-textured sample [1-2]. This shows very promising results for improving the friction and wear properties of contacting surfaces. Future work will further optimize the texture geometry and the laser micromachining techniques used to create the geometry through investigation of laser-material interactions.

Laser textured sample surface; the cylinder diameter is 18.75 mm. Laser texture features with a width of 100 microns, length of 400 microns, and depth of 25 microns.

Three dimensional view of a portion of a bar-shaped dimple. Neglecting discontinuities, maximum depth is approximately 25 microns.

Schematic of the experimental setup. A variable normal force is applied between the bottom of a steel cylinder and a thin strip of sheet steel. The strip is pulled at a constant velocity and pulling force is recorded.

Percentage reduction in coefficient of friction from a non-textured to a textured surface.

Algae Cell Attachment

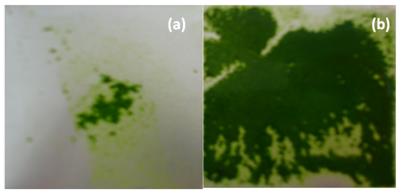

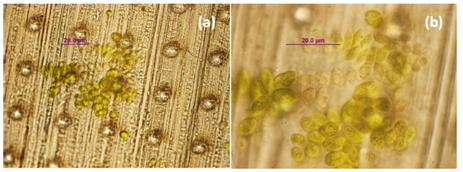

Another application for surface textures is improvement of cell attachment. A preliminary study was conducted in which stainless steel sheets were textured with micro-dimples. Algae were grown on textured and non-textured samples to determine whether improvements could be made in cell attachment. The images below show the textured samples before and after testing. A significant improvement in the attachment of the algae cells was found due to the textured surfaces [3]. These textured sheets can be used in algae farms in open ponds near the water surface, in which algae are collected for oil extraction. This method would reduce the cost of algae extraction since it would eliminate the need for expensive filtration; rather, the sheets are simply lifted and the algae are scraped off.

Sample laser textured surface before testing.

S. dimorphus grown on (a) as-received stainless steel surface, and (b) laser textured stainless steel surface. Thick layers of cells attached to the textured surface indicating that micro-scale surface textures enhance cell attachment.

(a) Microscopic photo of cells attached to dimples, 50x magnification; (b) 100x magnification photo.

Sponsors

Partnerships for Innovation in Laser-based Manufacturing and Materials Processing

NSF IIP award #0917936 – PFI (link)