Motivation

Textured or structured surfaces are finding a wide range of industrial applications in the fields of aerospace, illumination, tribology, and biomedical engineering. The elliptical vibration texturing process is an innovative machining method for the fast generation of textured surfaces. It adds a tertiary motion component to the tool tip, which introduces deliberate elliptical vibrations between the cutting tool and the workpiece. However, most tertiary vibration mechanisms suffer the drawbacks of either small vibration amplitudes or low output stiffness. Thus, a tertiary vibration mechanism with high amplitude vibrations and high stiffness is designed for the fast generation of textured surfaces.

Research Work

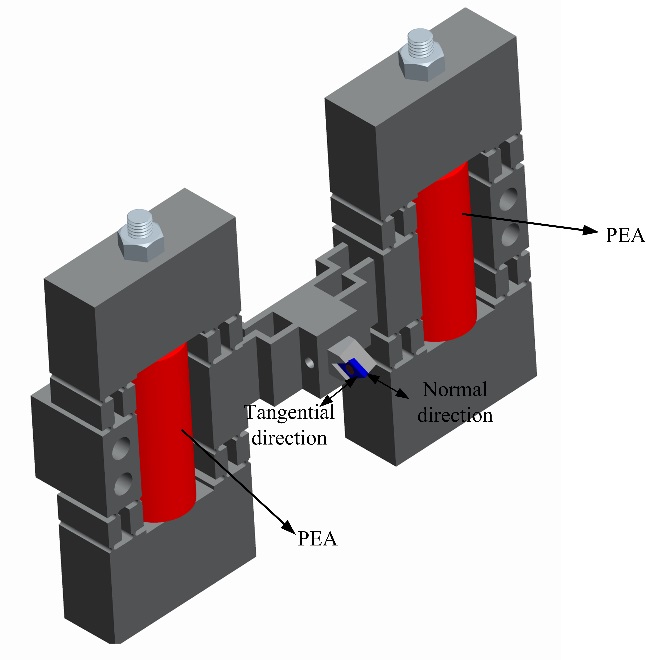

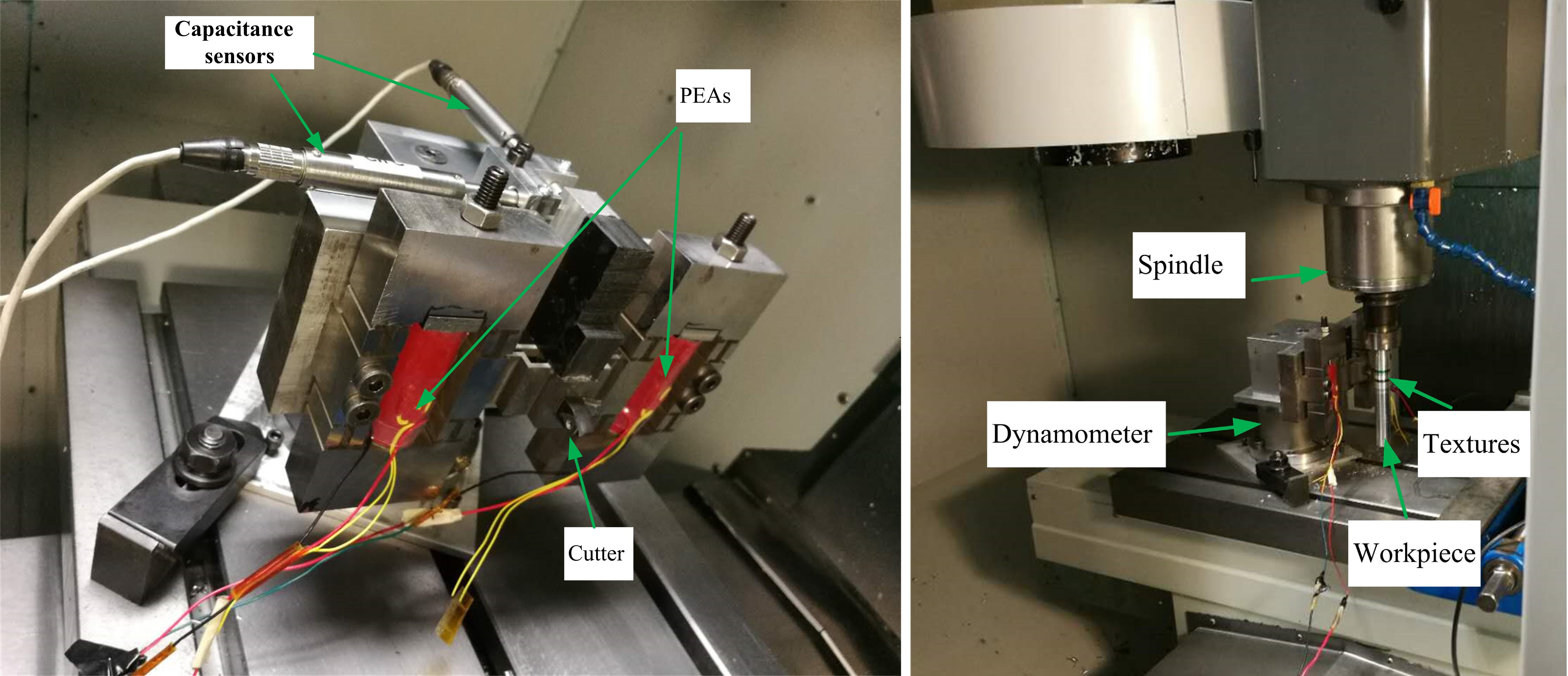

A novel high-stiffness/amplitude non-resonant 2D vibration-assisted compliant cutting system with in-process monitoring for surface texturing is designed and optimized. The performance of the 2D vibration-assisted compliant cutting system is tested. Then, various complex textured surfaces are generated by the 2D vibration-assisted compliant cutting system using a V-shaped diamond tool.

Photos

|

Fig. 1 Schematic of the designed 2D vibration-assisted compliant cutting system

|

Fig. 2. Experimental configuration

|

|

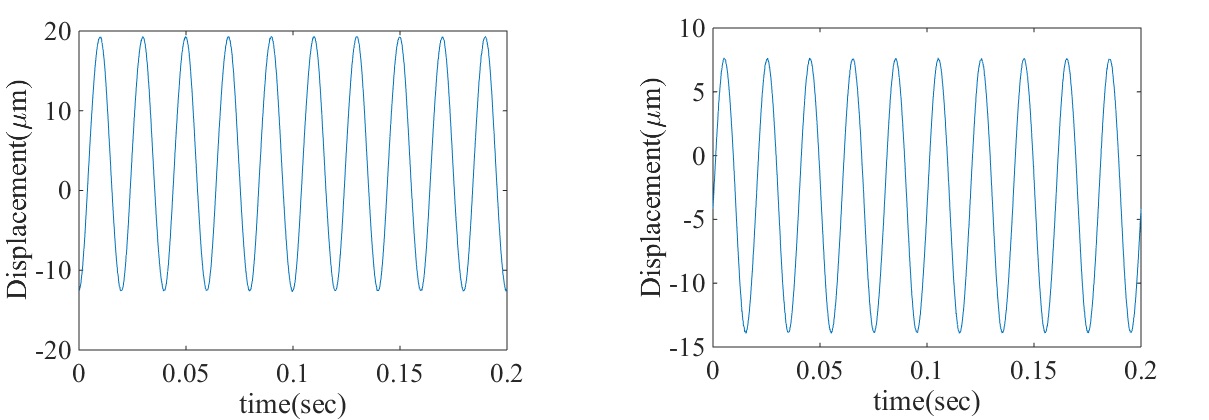

Fig. 3. Measured trajectory of tool tip (a) Vibration in tangential direction (b) Vibration in normal direction (c) Elliptical trajectory (f=50 Hz,Vp-p=400 V, phase=60 deg)

|

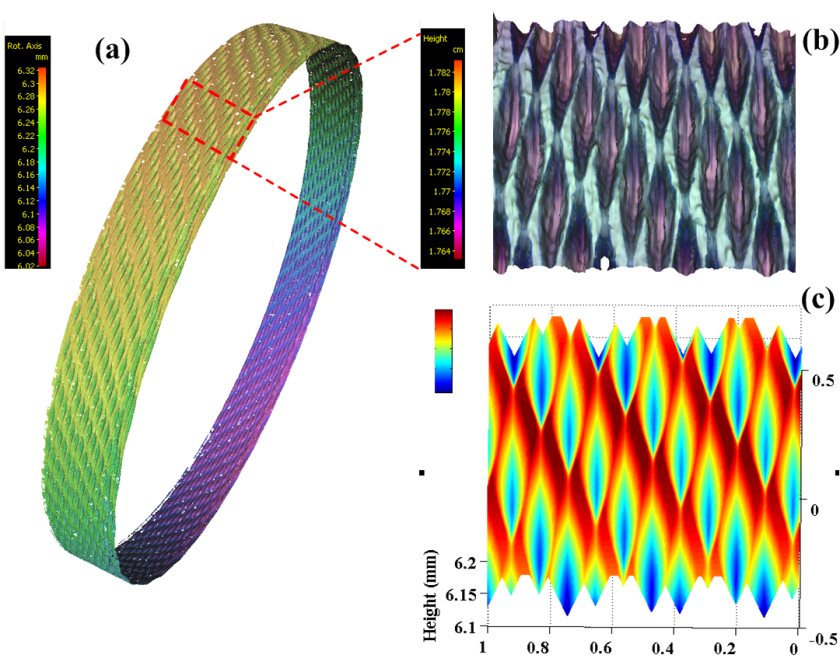

Fig. 4. Generate Textured surface (a) 3D measurement of micro-textures in 360º (b) Partial view (c) Theoretically generated surface (1.0 mm×1.0 mm)

|

|

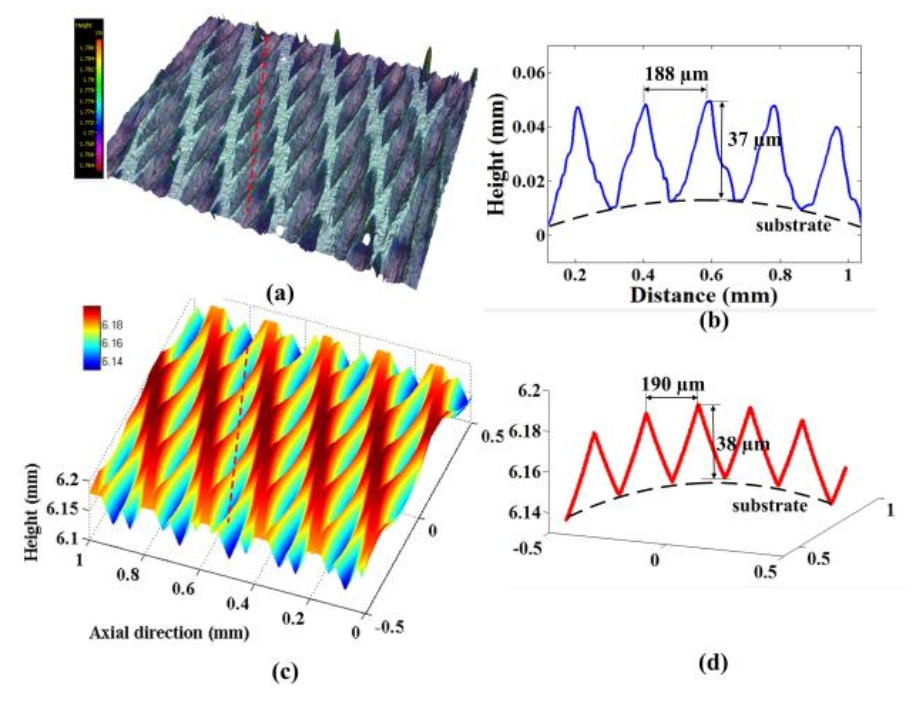

Fig. 5. (a) Measured topography of machined textures (b) Sectional profile from measured topography (c) Theoretically generated surface (d) Sectional profile of theoretical surface.

|

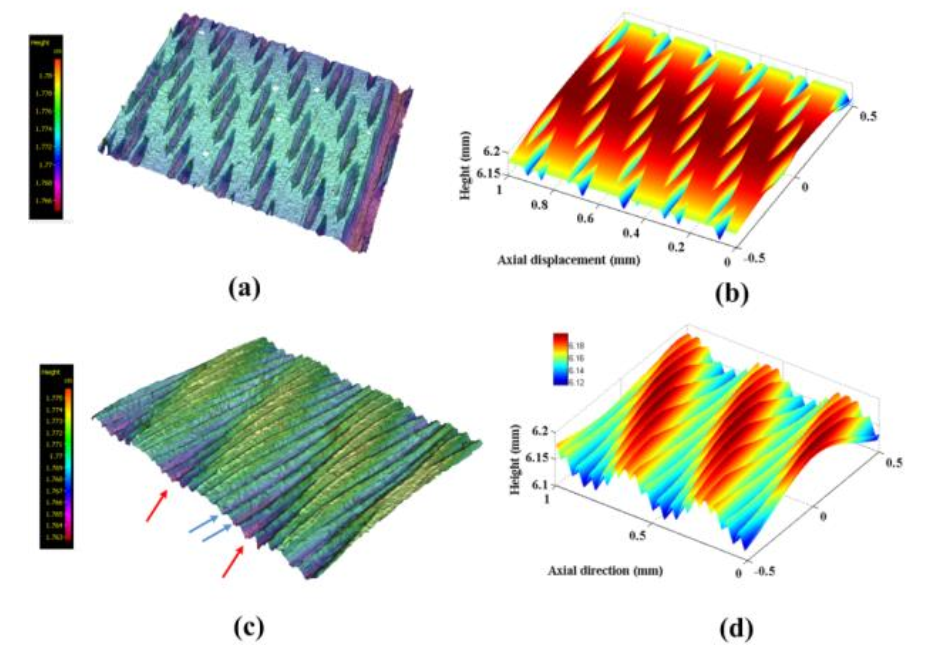

Fig. 6. (a) Machined textures with elongated dimple pattern (1.4 mm×1.0 mm) (b) Corresponding theoretical surface (c) Machined textures with hybridfeatures (1.4 mm×1.0 mm) (d) Corresponding theoretical surface

|