Motivation

The Additive Rapid Prototyping Instrument (ARPI) was developed to support fundamental research, technology development and education, in the fields of multi-physics (hybrid) additive manufacturing (AM) processes, machines and systems. This system is aimed at the rapid realization of products epitomized by multi-material structures and multiscale features. ARPI supports R&D on the dominant scientific and technological challenges related to the realization of integrated AM processing systems and on the understanding and modeling of hybrid processes and process chains. It is the first instrument of its kind, thus providing broad opportunities for multidisciplinary research and development of additive manufacturing processes, methods and equipment.

Description

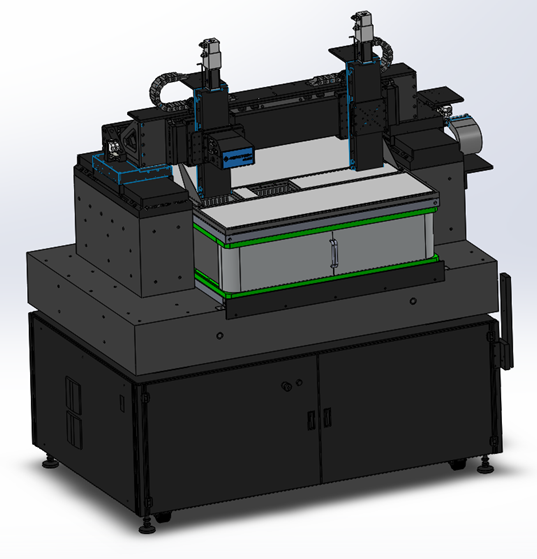

ARPI, as designed and built, is a multi-functional modular system composed of three subsystems (primary AM processing, secondary operations, and monitoring), each of which can function either in a stand-alone or integrated manner in a common command-and-control environment. ARPI provides an integrated processing platform and environment for enhancing part accuracy, surface finish, and material properties beyond the current capabilities of customary DED (currently the primary AM processing module). ARPI can be viewed as an advanced multi-functional 3D manufacturing platform offering the capability of future expansion as it is an open architecture instrument, easily reconfigurable for the exploration of new ideas.

ARPI Schematic

Sponsor

National Science Foundation (CMMI-1429658)