Motivation

|

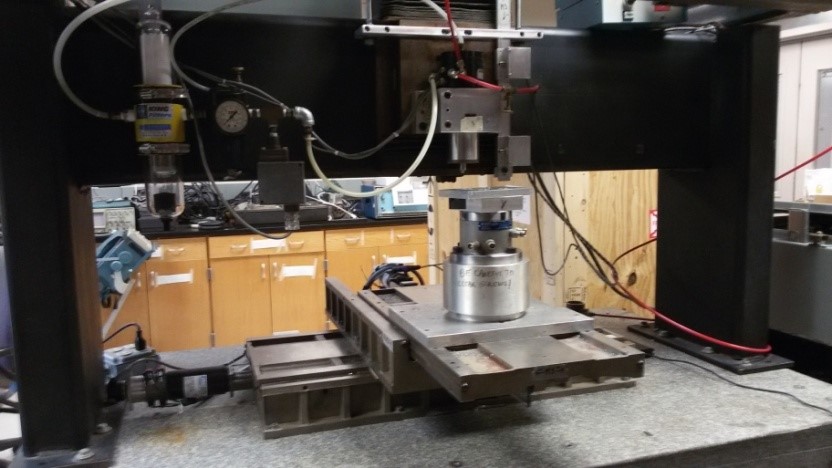

Fig. 1 Micro-milling machine

|

Micro-milling, frequently viewed as a downscaled traditional milling process, is widely used in precision manufacturing, electronic and biomedical industries. Compared to chemical manufacturing processes, the micro-milling process has the advantage of producing three-dimensional features with a broad range of materials. The mechanics and dynamics of micro-milling have to be modeled in order to predict the process behavior and plan the operations ahead of costly physical trials.

Description

One of the main research areas of micro-milling is to develop the process models to understand the micro-milling process better, develop simulation programs, optimization of parameters, etc. These models are integrated with graphical computation methods to identify tool-material contact for simulations of machining processes and cycles. The developed methods and computer programs have been applied to various industrial operations and parts.

Research Work

Investigating fundamentals of micro-milling process mechanics and dynamics, plastic/elastic deformations and chip formation, friction in metal cutting, ploughing and tool/material contact, machining dynamics, chatter stability and solution of chatter stability, analytical, multi-frequency and numerical models for investigation, process damping in milling process, surface generation and errors, etc.

Photos

|

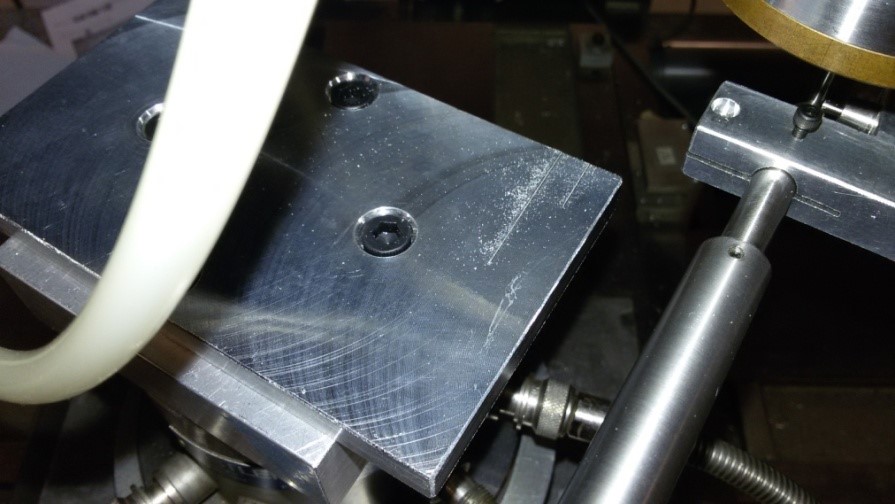

Fig. 2 Tool deflection measurements

|

Fig. 3 Machined workpiece in micro-milling process

|

|

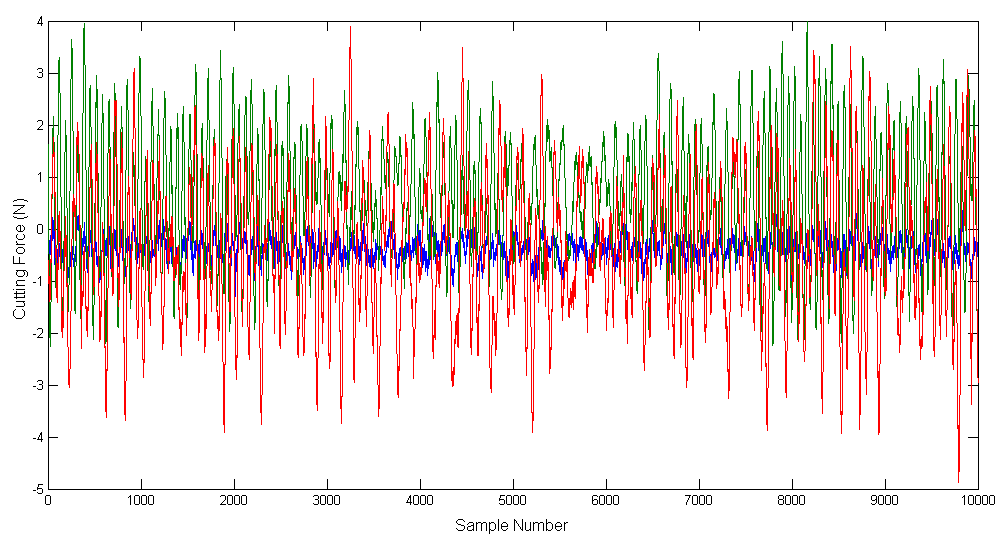

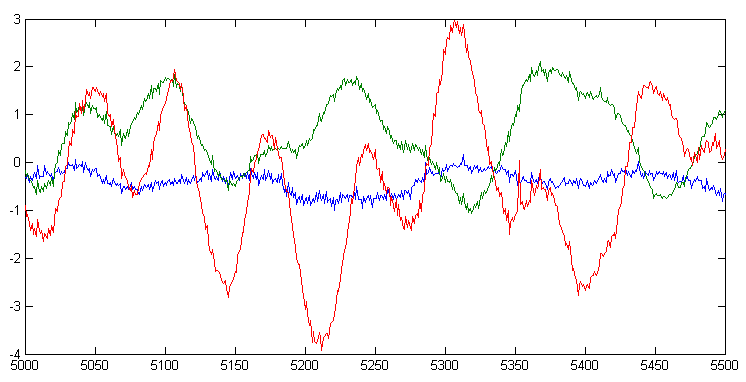

Fig. 4 Measured cutting forces in micro-milling process |

|

|

|

|

|

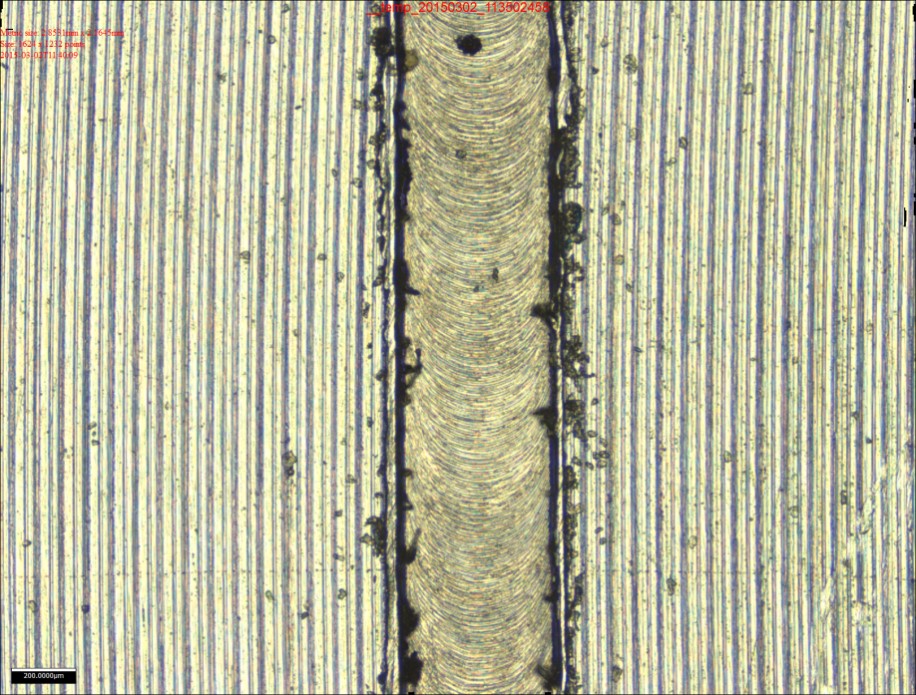

Fig. 5 Surface quality of machined workpiece

|

|