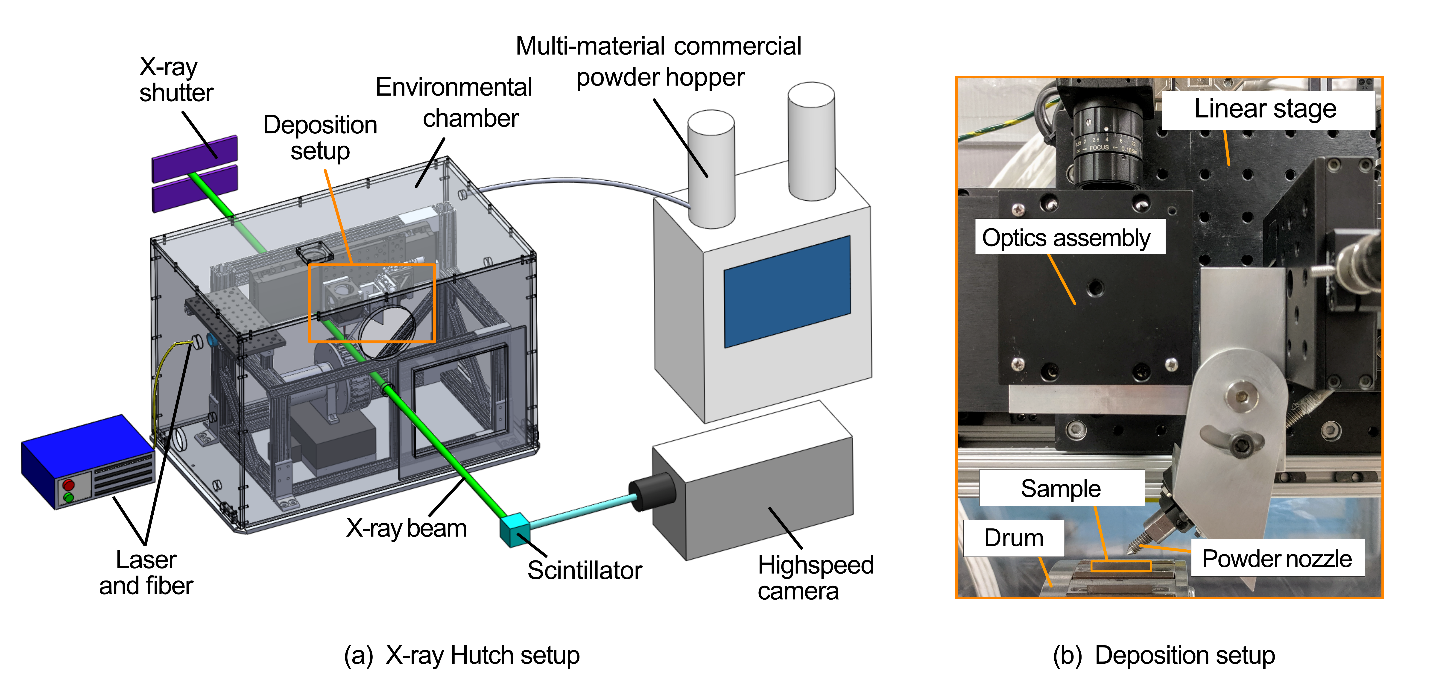

A custom-made, high-throughput DED apparatus used to deposit single and multi-layer clads in conjunction with in-situ highspeed X-ray imaging. The high-throughput DED system is designed to fit within the size limitations of an x-ray hutch. The deposition setup consists of a 1070 nm continuous fiber laser (IPG YLR-500-AC, IPG Photonics, USA), optic cube, in-house powder nozzle, and linear stage. The optic cube reflects and focuses the processing laser down to the rectangular substrate (30 mm x 10 mm, 406 µm thick) where the clad is deposited on the top side (406 µm) of the substrate using a single-axis linear stage. Collected images are perpendicular to the laser and scan direction such that clads are imaged in the 30 mm x 10 mm substrate plane. A commercial powder delivery system can be used (PF 2/2, GTV, Germany) to deliver industrial rates of powder, and the deposition setup is housed in an environmental chamber purged with Argon.