Motivation

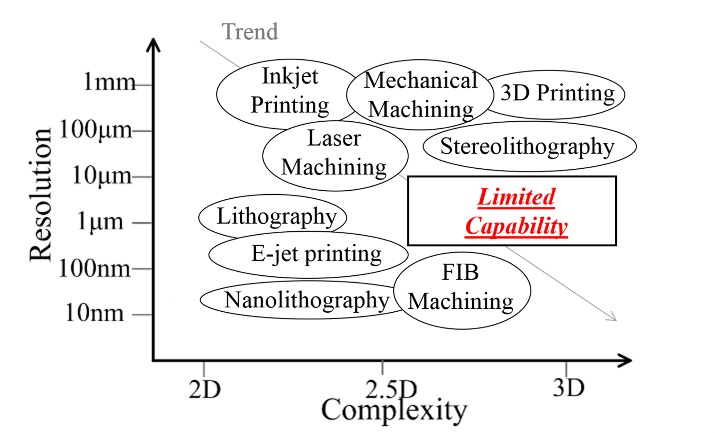

Fig. 1. Current micro- and nano-manufacturing technology landscape.

Technologies with single-micron andsub-micron resolutions capable of

producing complex shapes are not currently available.Product miniaturization has created a need for novel manufacturing methods capable of producing complex geometries with resolutions in the nano- and micro- scales. Ideally these new micro- and nano- manufacturing techniques should have high throughput and multi-material capabilities.

Description

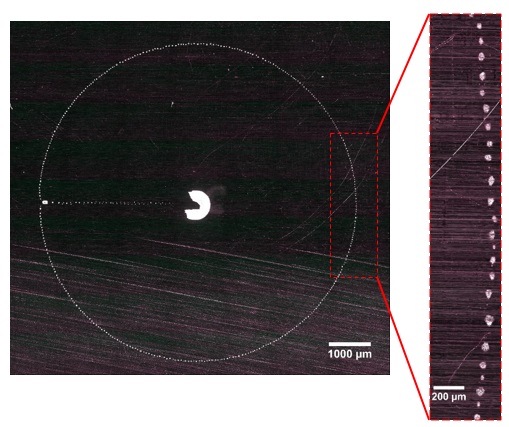

Near Field Electrospinning (NFES) is an additive manufacturing process that can achieve micron and submicron resolutions. This process uses electrohydrodynamic phenomena to create continuous micro and nano fibers (diameters have been reported as low as single digit nanometers and up to several microns). The fibers can be deposited in a moving collector to generate 2D and 3D structures. NFES has been shown to be compatible with hundreds of polymers. The technology is being expanded to produce micro-bead arrays. By using dilute inks, it is possible to obtain beads with diameter from 10 µm to 200 μm. The beads can be used for texturing of surfaces.

Approach

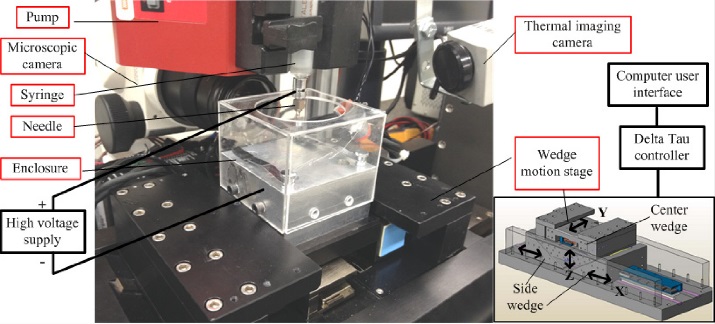

Fig. 2. NFES experimental setup

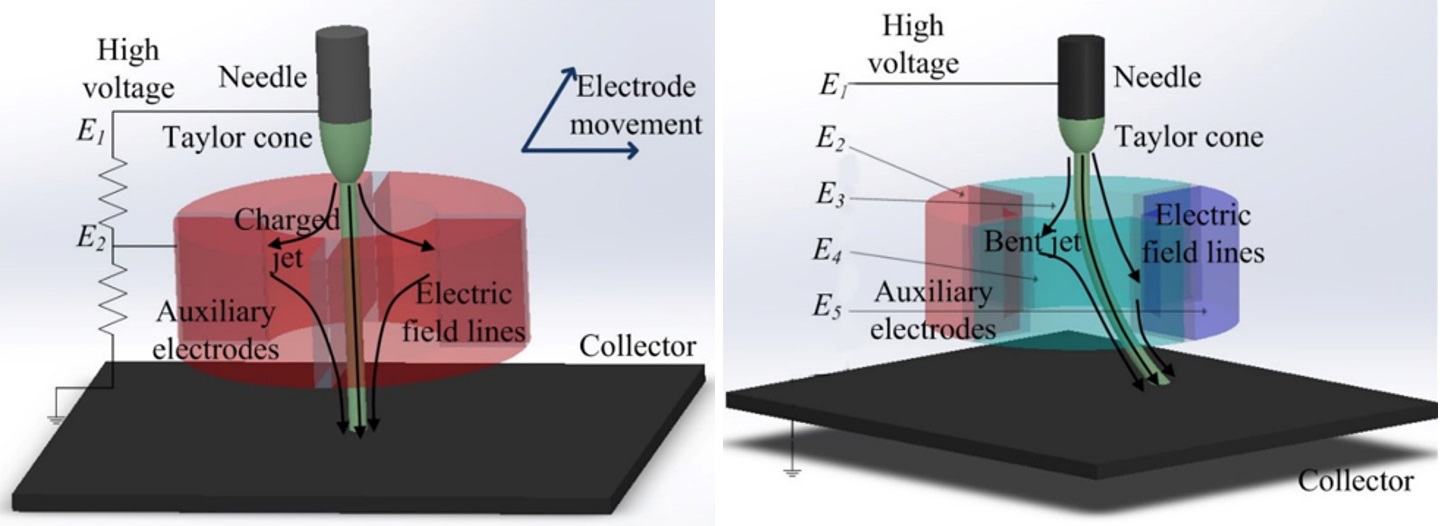

NFES must overcome challenges in control, throughput, and repeatability to become a viable manufacturing technique. We have developed an NFES setup to study the physical phenomena involved and to test new control methods. Currently, we are studying the feasibility of electric field modifications to control the fiber deposition process. The electric field modification is achieved by using auxiliary electrodes and modifying the geometries of the electrodes required for NFES. This should allow for tighter resolutions and increased repeatability. A multiphysics model is being developed to aid in the design of the setup. The model will be extended to solve backward control problem, i.e. predict the required parameters for obtaining a desired geometry. Finally, a close loop control system based on machine vision is being developed to improve process reliability.

Fig. 3. Conceptual electrode ring designs for fiber control. The control is based on electrode

piezo-actuation (left) and electrode potential variation through time (right).

|

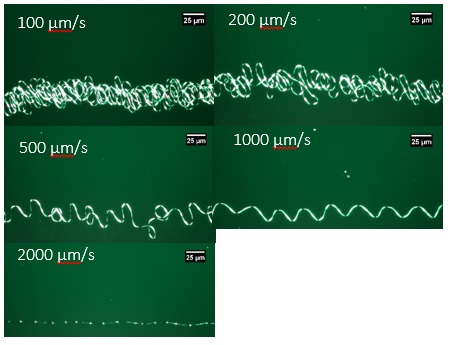

Fig. 4. Deposition of nanofibers with varying stretchability.  |

Fig. 5. Deposition of circle made of micro-beads.  |

Sponsor

National Science Foundation (CMMI – 1404489)