NSF CPS: Synergy: An Integrated Simulation and Process Control Platform for Distributed Manufacturing Process Chains

Volumetric Representation

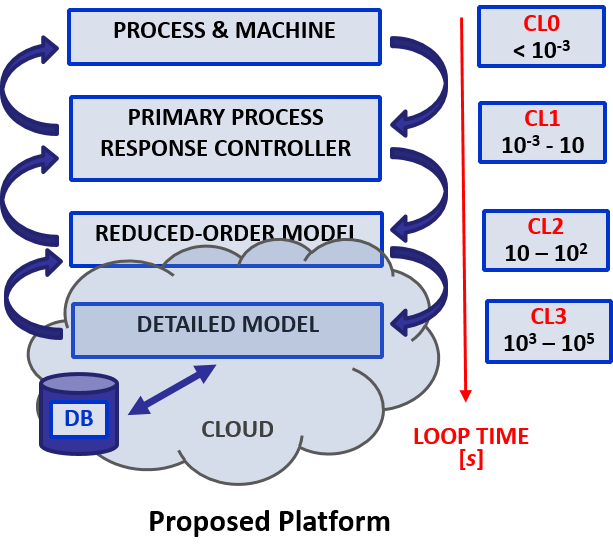

This research will establish the scientific and technological foundation for a futuristic manufacturing platform in a distributed network that seamlessly and efficiently integrates physical processes and numerical simulations in a fast predictive framework. This platform will be powered by next-generation cyber-physical infrastructure to control desired part characteristics in terms of attributes/properties such as microstructure, porosity, residual stresses, and geometric and surface features. The envisioned cyber-physical engineering platform will allow users to quickly determine the process parameters needed to yield the desired part attributes in a given process or process chain. The landscape of manufacturing is gradually becoming predominantly digital due to the emergence of Cyber Physical Systems. At the forefront of this innovation are processes in which geometrically and structurally complex parts based on digital models (CAD) can be produced. In spite of their flexibility, the functional properties and performance of the produced parts is difficult to predict. This research targets the formulation of a new processing platform in which part geometry, process parameters, numerical process simulation, and predicted mechanical behavior all interact via a common data structure for process control and certification. The part geometry (from CAD), analysis meshes and part properties will all be saved through an innovative volumetric representation providing a common data structure, optimized for performance on Graphical Processing Units (GPUs). The feasibility of these models and of the proposed platform to achieve the desired part properties will be demonstrated on a unique fully-instrumented open-architecture networked machine: Directed Energy Deposition (one form of additive manufacturing).