Waterjet-Guided Laser Processing System

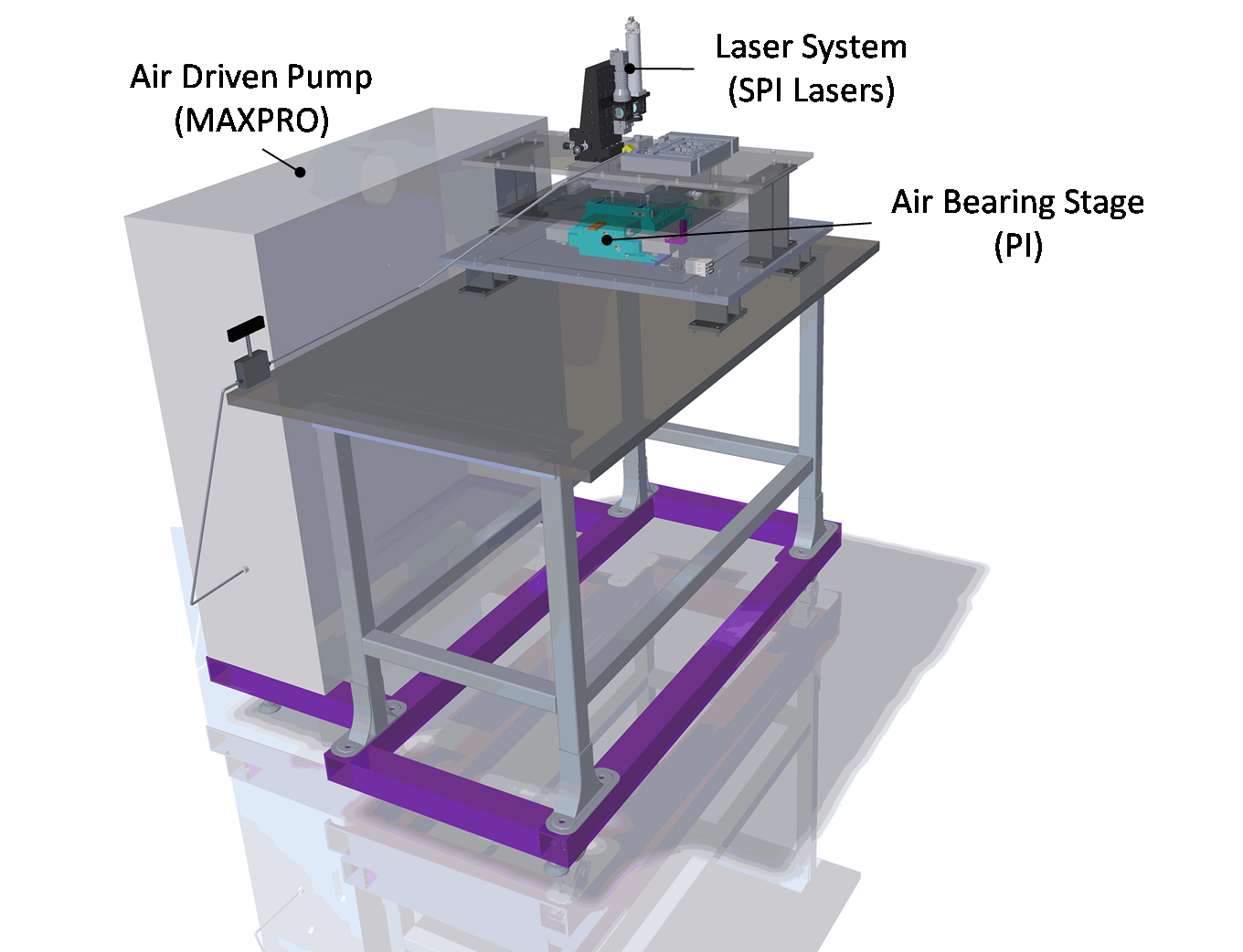

Fig. 1. Overall design of the waterjet-guided Laser Processing

The entire setup consists of three main systems. Two axes air bearing positioning system for moving the samples. High-pressure waterjet system forms the micro waterjet by transferring air pressure to water pressure and then pumping the water through a diamond orifice. SPI fiber laser is selected to couple with the waterjet. Fig. 1 shows the entire design of the system for water-jet guided laser processing.

PIglide Precision Air Bearing Stages

Travel Range: 100x100 mm

Maximum Velocity: 1 m/s

Maximum Acceleration: Up to 1 g

Accuracy: ± 5 μm

Repeatability: ± 0.5 μm

MAXPRO Air Driven Pump

Maximum Water Pressure: 450 MPa

Air Pressure Input: 0-0.56 MPa

Magnification Ratio: 796:1

SPI G4 Pulsed Fibre Laser

Average Power: >70W

Wavelength: 1070 nm

Frequency: 70-1000 kHz

Pulse Width Range: 10-500 ns

Beam Quality (M2):<1.6